The Toyota Way is a set of principles and behaviors that inspire the Toyota Motor Corporation’s managerial approach and production system. Toyota first summed up its philosophy, values and manufacturing ideals in 2001, calling it “The Toyota Way 2001”.

Heritages of the Toyota Production System

The ‘Toyota Way’, was established from The Toyota Production System (TPS), which is based on the philosophy of complete elimination of all waste in pursuit of the most efficient methods, which has roots tracing back to Sakichi Toyoda’s automatic loom. TPS has evolved through many years of trial and error to improve efficiency based on the ‘Just-in-Time’ concept developed by Kiichiro Toyoda, the founder (and second president) of Toyota Motor Corporation. Waste can manifest as excess inventory, unnecessary processing steps, and defective products, among other instances. All these “waste” elements intertwine with each other to create more waste, eventually impacting the management of the corporation itself.

Kiichiro Toyoda, who inherited this philosophy, set out to realize his belief that, “the ideal conditions for making things are created when machines, facilities, and people work together to add value without generating any waste.” He conceived methodologies and techniques for eliminating waste between operations, both lines and processes. The result was the Just-in-Time method. This concept provides a vision of flowing value directly to the customer without interruption. Increasingly, customers want customized products and services on demand. Furthermore, ‘Built-in-Quality’ concept follows the principle of doing it right the first time to avoid downstream modifications.

The foundation of the TPS house clearly suggests it is not possible to flow value smoothly and perform each step correctly, when there is disorder and instability. Hence the need to level the flow of work to make it steady and consistent. Many manufacturing and service organizations that have followed these principles have had dramatic success in eliminating waste, streamlining processes, saving money and better serving customers. As seen in the image below, the goal on the roof of the TPS house suggests that doing these things will improve quality, cost, delivery, safety and morale. It is shown as a system in which all the parts are interconnected, as in a structure—like a house.

Nevertheless, the people aspect who are supposed to be building and rebuilding the TPS house (applying the concepts) to familiarize to a dynamic environment are missing in the image, which brings us to the invention of the “Toyota Way”.

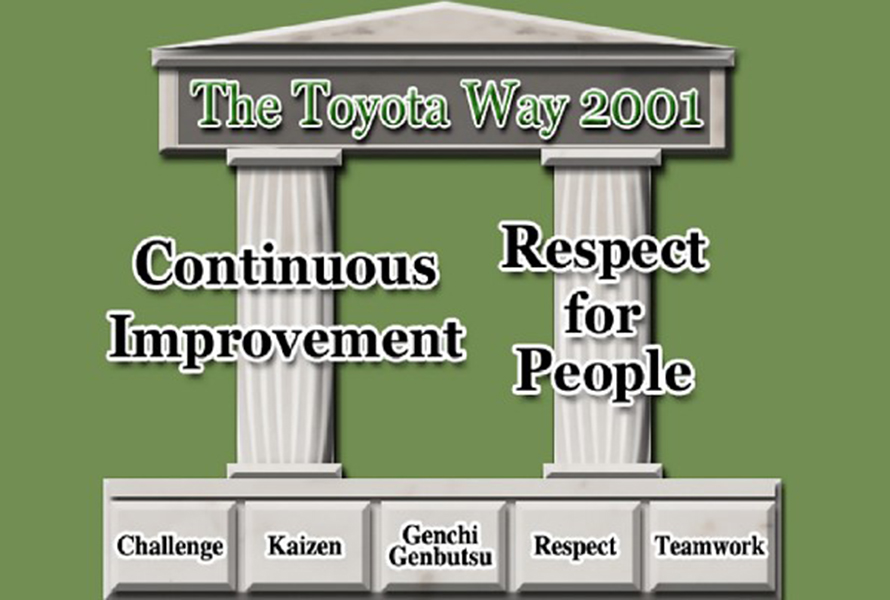

In 2001, Toyota created the “Toyota Way “house as an improved version house from the TPS house, which consists of principles in two key areas: continuous improvement, and respect for people. The ‘Toyota Way’, was defined in a simpler framework for applying Toyota’s Guiding Principles and building the kind of company that people should apply in every aspect of their day-to-day work livelihood, globally. It is the foundation of Toyota corporate culture. The new renovated ‘Toyota Way’ House is built on two pillars: Continuous Improvement, which takes in the concepts of Challenge, Kaizen and Genchi Genbutsu, and Respect for People, which embraces Respect and Teamwork, and gives a clear corporate direction as shown below:

1. Continuous improvement

Challenge

When we embrace a challenge we also commit oneself to challenging what we know and do to complete it. This means we have to approach each challenge, not only with creativity, but also with passion and courage.

Kaizen

Kaizen is the essence of continuous improvement. It is a way of thinking which encourages and empowers everyone to identify where and how even small changes can be made to benefit the business, the team or an individual performance.

Genchi Genbutsu (現地現物)

Genchi Genbutsu literally translates “real location, real thing” and it is a key principle of the Toyota Production System. The principle is sometimes referred to as “go and see”. It suggests that in order to truly understand a situation one needs to observe what is happening at the site where work actually takes place, the genba (現場). One definition is that it is “collecting facts and data at the actual site of the work or problem. To achieve this one has to go to the source. “Going to the source” – is about checking the facts oneself, so that one can be sure to have the right information needed to make a good decision.

2. Respect for all at the heart of our business

Respect for people

This focuses on the relationships among colleagues, it is important that everyone is respected both for what they contribute and who they are. That includes an employees’ ideas, cultural and personal beliefs. Through Respect everyone in a corporation will have a personal responsibility for what they do and build mutual trust and understanding, which will aid build a diverse and sustainable workforce that reflects society around us and our changing customer base.

Teamwork

Successful teamwork is about everyone understanding corporate goals and working together to achieve them. Every member of a team is given the opportunity to do their best and is accountable to achieve results, Just-in-Time. Notably, throughout our business, from the board room to the production line, we recognize that people are our greatest asset. We strive to give human resource stable employment in line with the ‘Toyota Way’ with opportunities to develop their skills, responsibilities and commitment as individuals and committed team members.

The “Toyota Way” has been adopted not only by companies in Japan, Toyota companies worldwide, within the automotive industry, but also in production activities and continues to evolve globally.